What is WeProd ?

WeProd is a French owned manufacturing startup directly located in Shenzhen and is founded by rmanufacturing expert (not someone who only lives in China or an Chinese speaking westerners) with real manufacturing operations experiences in China with root trained in France and USA.

We help hardware oversea companies to handle their manufacturing in China by offering pragmatic and down-to-earth supports.

We can support your team for product design, prototyping, industrialization, supply chain, production, logistic, project management, suppliers management/monitoring, manufacturing problems firefighter.

As supply chain for electronic components are tougher and tougher, we also help clients to source electronic components or to re-design electronic using Chinese alternative components.

Because of strict covid policy in China and travel to China is almost impossible, containers booking is a nightmare, we can also help you to monitor suppliers, support production directly on site and make sure all is going smooth and no delay to meet containers pick up and shipment on time.

Clients and team co-working at WeProd

Language difference is not a problem, there is always a way to communicate

Hands on

Assembly of prototypes of French e-skateboard before mass production

Automomous delivery robots production

Agile organisation to support the Colombian startup from Berkeley at its very beginning

Client ask to make the impossible possible

Trying to make an Australian e-skateboard be waterproof whereas it is not waterproof designed

Shenzhen manufacturing meetups

Meetup of the UTSEUS network with engineer students

Covid situation in China

Zero covid policy in China has big impacts on business, WeProd can support your team in China.

We can support in product design, production and quality inspection. We also intervene at supplier's factory to implement new working processes to be able to work remotely with proper working documents and review such engineering change notification or approval shipment process.

Because having deep quality problems analysis is difficult to manage from overseas, we also go on-site from quality problem solving to the implementation of effective countermeasures on production lines.

We can support in product design, production and quality inspection. We also intervene at supplier's factory to implement new working processes to be able to work remotely with proper working documents and review such engineering change notification or approval shipment process.

Because having deep quality problems analysis is difficult to manage from overseas, we also go on-site from quality problem solving to the implementation of effective countermeasures on production lines.

Feel free to leave us a message below in our contact box, we will be glad to advise you and support you on-site directly.

MouldsWeProd partners with an exclusive mould supplier in Dongguan to guarantee constant quality and lead time.

Also for each mould, you will be issued an ownership certificate and all discussion during the mould working process will be held with the mould supplier tri-partite meetings. The mould supplier is independent, no mould hostage, your moulds will be available anytime anywhere. |

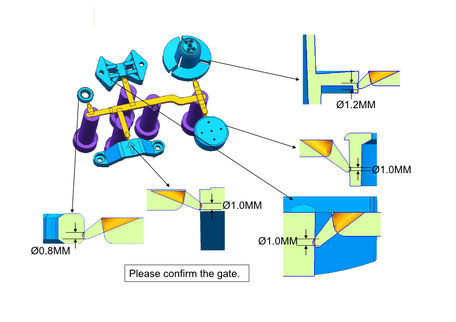

Mould working process

Mould manufacturing usually takes 6 weeks minimum from study to completion.

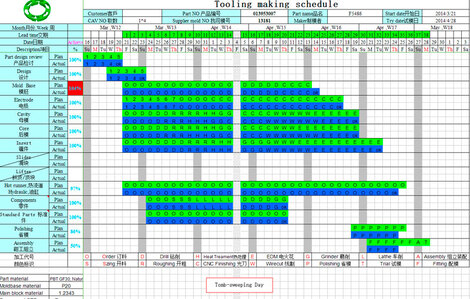

Planning set up and review

Schedule will be made to meet as much as possible the client's expectations. Plan VS actual status will be tracked via weekly project report which includes all status about mold base, cavity, electrodes, components, CNC machining, EDM, wire cutting, polishing, fitting.

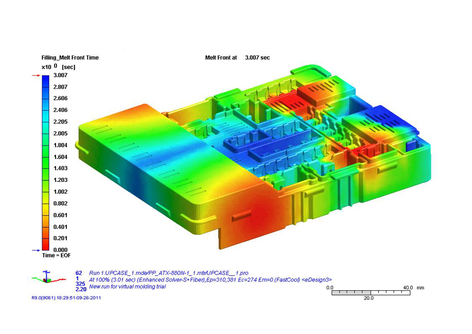

Mould flow analysis

Mold flow analysis report is necessary to ensure tooling quality, specially for big or complex part, or resin with easy deformation character,through analysis, proper gate position, efficient cooling system, identify the potential melting line, air trapping, sink mark and warpage, all technical risks mitigation are through mold flow analysis.

Design review for manufacturing

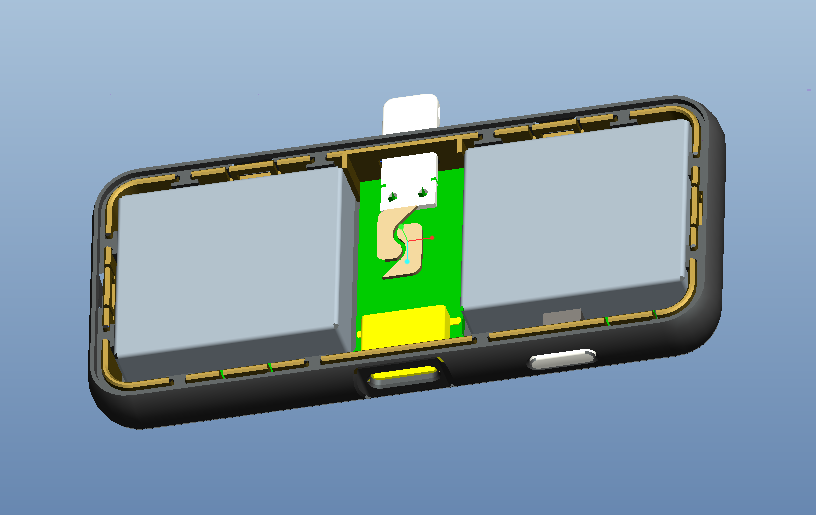

Design review for manufacturing (DFM) will be processed right after 3D data availability, prior to tooling design, DFM report detects all key details of tooling design and fabrication, eg. Tooling structure, parting line, gating system, cooling system, ejection system, simple mould layout, draft angle, drawback of part design, we also point out recommendations for design changes.

Mould design

After acceptance of the DFM and some design changes, we start the design of the tooling and the purchasing of material for tooling.

Prior the start of the mould manufacturing, we will review the mould with the client to make sure we have taken all requirements into account.

Prior the start of the mould manufacturing, we will review the mould with the client to make sure we have taken all requirements into account.

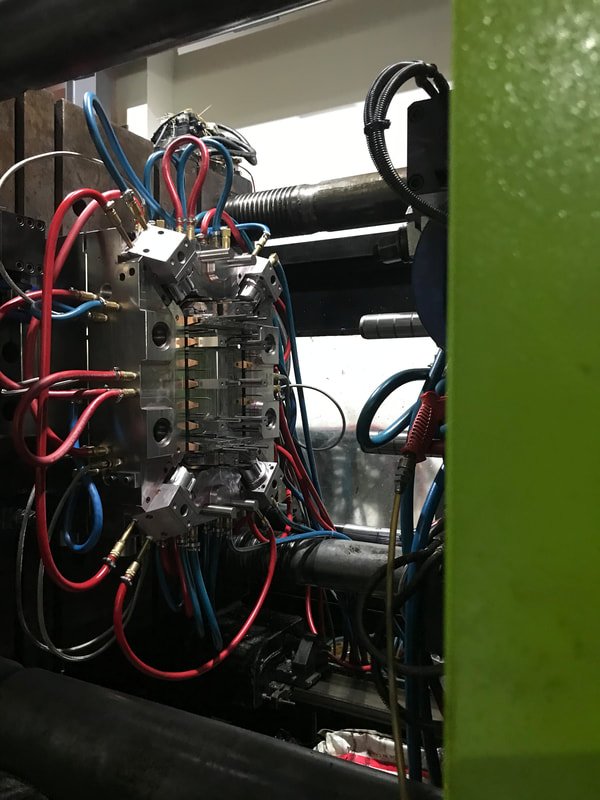

Mould manufacturing

Mould design review done and agreed by the client, we then start the manufacturing of the mould. The process is the longest in our mould processing work.

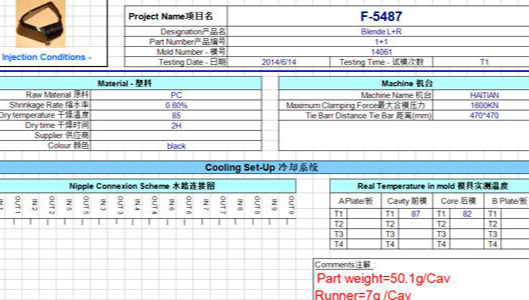

FAI and test report

The test report is an important milestone to make sure the part fulfill the specifications. It provides the injection parameters recommendation, first article inspection check (visual + dimensions)

Countermeasure loop (if needed)

After the FAI and test report, we may need to change some small design changes or change the graining of the parts. After we re-do a pilot run, new FAI and test report.

To finish a fully assembled prototype, we need approximately about 20 days.

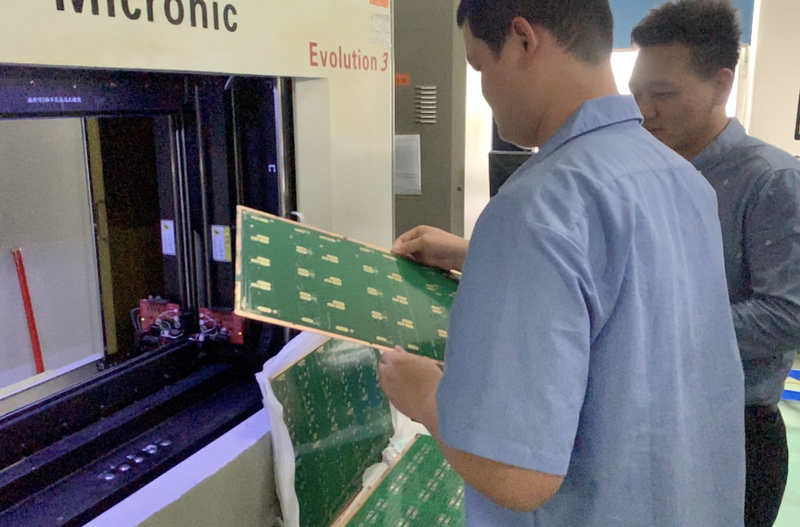

PCB

PCB manufacturing needs 5 days

PCBA

PCBA is longer because of the components purchasing that may take 1 to 2 weeks, then the SMT will only 3 days depending on the machine work load. Prior to PCBA manufacturing, make sure you also define how to test the PCBA and software preparation. We may spend time to test the PCBA.

3D printing

3D printing is usually done from 24 to 48 hours

CNC machined parts (metal or plastic)

CNC machined parts often take about 1 week depending on the quantity needed

Silicone

We can do a temporary mould within 1 weeks (the longest is to do the CNC part for the mould) and then production for 1 to 2 days.

Assembly

The assembly takes only 1 or 2 days depending on the complexity of the device to assemble. But we need to prepare in advance the sourcing and purchasing of components to be ready. During assembly we may have some problems because it will be the first time doing assembly (components not correct, fitting issue, assembly issue, functionality issue)

Kim (Pictured above in purple) was born and raised in France. Kim holds a master’s degree in mechanical engineering in 2002, he has been living in Shenzhen since February 2006. He speaks French, English and obviously Chinese.

He founded WeProd with the simple idea of making things simple in manufacturing in China because of his background from Toyota, he learnt to see manufacturing through simple concepts as Lean, Genchi Genbutsu, Poka Yoke. Moreover, He has earned his stripes in factory operations working as quality manager and general manager of factories in China manufacturing electronic devices, plastic injections, and metal products.

He founded WeProd with the simple idea of making things simple in manufacturing in China because of his background from Toyota, he learnt to see manufacturing through simple concepts as Lean, Genchi Genbutsu, Poka Yoke. Moreover, He has earned his stripes in factory operations working as quality manager and general manager of factories in China manufacturing electronic devices, plastic injections, and metal products.

He has a deep knowledge of the whole manufacturing processes in China on all kind of production processes like plastic injection, silicone, metal processing, rubber, pcba, surface treatment, wood.

Any questions ? feel free to drop us a message below using the contact box

Conference calls are a part of our routine

Our clients are overseas mainly Europe and USA

Even early in the morning or late at night

We design products

We are testing a connected piggy bank with lots of problems for the French public post company

We usually do a product analysis to see if we can start from an existing product to have the cost down

We test protos on site

Testing of UWB device to count points autonomously on basketball court for a well known French sport goods retailer

Agile, quick loop tests and fast design change

We have agile and flexible workshop

Scaling the assembly of microphone for a Chinese company

Small production cells similar in Toyota factories

We trust our suppliers but we control them

inspection of packaging for a French medical device company

We want to make sure our clients' requirements are fully met

We enhance quality with simple ideas

Inspection of vape chambers for an American vape pens company

Like this magnifying glass to see very small cracks inside the atomizer of a vape

Check out some of our projects

We have projects in different phases: design, prototyping, pilot run, supply chain/sourcing, mass production and project management.

We not only have electronic devices projects, but we also have non electronic projects such bathroom products, metal components, sourcing of electronic components.

We not only have electronic devices projects, but we also have non electronic projects such bathroom products, metal components, sourcing of electronic components.

Our projects are from individual entrepreneurs, startups, SMEs and also well known group (as you may find out in our projects photos above)

Currently in 2021 and 2022, we have been working intensively on battery and mobility. We can assist you for e-bike, e-scooter and battery packs (even swapping batteries), components with our network of suppliers.

We also have suppliers for EV chargers manufacturing and distribution. No matter where you want to set up an EV chargers stations, we are able to support you in the installation of the stations. Feel free to drop us a message below !

We also have suppliers for EV chargers manufacturing and distribution. No matter where you want to set up an EV chargers stations, we are able to support you in the installation of the stations. Feel free to drop us a message below !

How can we support your crowdfunding campaign ?

We are working with few crowdfunding projects by bringing our manufacturing expertises to the teams.

The most challenging is the planning displayed on the campaign, many planning move because on unexpected problems such as components shortage or long leadtime, or because the design was not actually finished or need to be updated following review of design on electronic or mechanical parts, or the suppliers are getting impatient because the project is taking ages, or the suppliers is not cooperated.

We are down-to-earth so we will tell you the real situation to find solutions asap, some listen and some don't listen then the project is taking more time or the project never go out.

Coming from Kickstarter, Indiegogo or Ulule, lots of entrepreneurs are coming to Weprod for questions like:

- Where to do the production ? in Europe or in USA or in China ?

- What to do as my CM dropped us ?

- What to do as my mould supplier is holding my moulds ?

- How to communicate with suppliers or CM ?

- How to make sure my suppliers follow my requirements ?

- How to make sure the location i visited is the supplier's location ?

No question on manufacturing is dump, feel free to drop us a question, we usually answer within 24 hours.

The most challenging is the planning displayed on the campaign, many planning move because on unexpected problems such as components shortage or long leadtime, or because the design was not actually finished or need to be updated following review of design on electronic or mechanical parts, or the suppliers are getting impatient because the project is taking ages, or the suppliers is not cooperated.

We are down-to-earth so we will tell you the real situation to find solutions asap, some listen and some don't listen then the project is taking more time or the project never go out.

Coming from Kickstarter, Indiegogo or Ulule, lots of entrepreneurs are coming to Weprod for questions like:

- Where to do the production ? in Europe or in USA or in China ?

- What to do as my CM dropped us ?

- What to do as my mould supplier is holding my moulds ?

- How to communicate with suppliers or CM ?

- How to make sure my suppliers follow my requirements ?

- How to make sure the location i visited is the supplier's location ?

No question on manufacturing is dump, feel free to drop us a question, we usually answer within 24 hours.

Why work with WeProd ?

WeProd is your trusted "middle man" to do business with Chinese partners

We are down-to-earth mindset, we will tell you directly problems of your design/product/team or of the suppliers to find solutions quickly

We are completely independent

We have western culture and we know the Chinese culture of doing business

We represent the interests of your company by defining the objectives of the partnership with your Chinese partners

We work for the benefits of your business as a whole, we handle the meetings on your behalf

We maintain close, constructive relations with the Chinese partners you chose while retaining your independence

We intervene as a mediator to lean relationship and protect your interests and move forward fast

We treat your business with fairness and integrity

We are completely independent

We have western culture and we know the Chinese culture of doing business

We represent the interests of your company by defining the objectives of the partnership with your Chinese partners

We work for the benefits of your business as a whole, we handle the meetings on your behalf

We maintain close, constructive relations with the Chinese partners you chose while retaining your independence

We intervene as a mediator to lean relationship and protect your interests and move forward fast

We treat your business with fairness and integrity